Storage small warehouse for rent in Mason, Ohio is a significant portion of your business. However, when run inadequately, they can be hazardous spots for your laborers to work in. It is essential to survey typically and assess how you can improve your storage warehouse condition to guard your laborers.

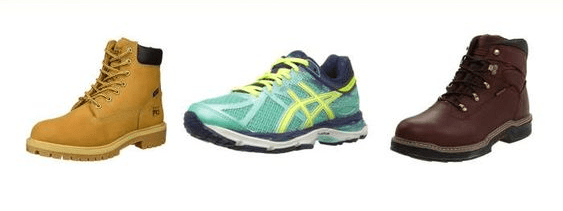

Both as far as keeping everybody safe and boosting efficiency levels, a very much controlled warehouse is imperative for your business. For storage warehouse laborers, the correct shoes fill in as their definitive defense towards guaranteeing that they don’t experience the ill effects of the knee, heel, and back aching.

It is essential to find the best shoes for warehouse pickers in order to avoid complications. Always remember that whenever left uncorrected, such diseases can additionally bring about progressive foot concerns, for instance, plantar fasciitis.

Here are seven tips to actualize in your bonded warehouse environment to ensure the safety of your pickers. Every one of these suggestions will help guard your laborers, while additionally keeping business running efficiently.

1. Recognize All Sort Of Risks

It’s essential to require some investment and assess the expected issues and perils in the storage warehouse center. Look for small slip and outing risks, such as links left dangling or an obstruction standing out at an irregular edge. In any event, harmless-looking risks as a pencil can result in a slipping danger in case somebody is hurrying past and steps on it.

Are there any breaks or gaps in the floor of the storage warehouse center? Other than being an excursion danger, they can likewise cause issues for the pieces of equipment, for example, forklifts, making them become wrecked or hurt one of your laborers. Set aside the effort to assess what could be an issue. Invest in best shoes for warehouse pickers so that your pickers can steer away from injuries.

2. Up-to-the-minute Training

Up-to-the-minute, training is a significant portion of any all-around stockpiling distribution center. Other than guaranteeing that your staff work at their most effective rate, it likewise implies that training can comply with all the more regularly up-to-the-minute. It is effortless to compromise for accelerating work or because it has been continuously done along these lines.

Through conventional training programs, you can stay up to date with how they can maintain a strategic distance from risky working practices, just as a guarantee, they recognize what to do if there should arise an occurrence of a mishap or spill. A superior educated workforce is, in every case, better for business.

3. Capacity

Your storage warehouse center makes sure to be brimming with stock and different things. Significantly, such items are put away securely. Ill-advised capacity can harm the stock; however, it can likewise hurt your pickers. There are various best shoes for warehouse work that can help speed up the pickers’ work. Inappropriately stacked boxes on high retires can fall effectively, conceivably harm somebody. Keep such loads stacked correctly. In this way, that hazard is inconceivably decreased. So also, by stacking objects in littler stacks, it is more unaffected and secure for your staff to recover things.

Additionally, make sure to encourage pickers on the right lifting procedures to keep away from any potential bruises or fractures when lifting something.

4. Tidiness

A spotless and a kept up storage warehouse is a more secure place for the warehouse pickers. By keeping your workspace stainless and clean, there’s less danger of slip or excursion jeopardizes. Everything ought to have its place. Your workers should watch out for what necessities to go where on account of the training methodology you’ve administered. Urge your pickers to tidy up after themselves and wear the best shoes for warehouse work. In the event that liquid spills on the floor, its tidy up should be settled before whatever else.

Some stockpiling distribution center situations manage possibly risky material. For this situation, keep up proper convention and guarantee that such materials are put away securely and unmistakably checked so that there’s little spillage danger.

5. Hardware

Fundamentally, you should use the proper security gear. Hard-hats and the protective eyewear can be a substantial part of some sheltered warehouse center. Nonetheless, extra hardware, such as high porosity overgarments and best shoes for warehouse workers, is similarly assistive.

It’s likewise considerable that any determinate gear, such as sprinkler and warning alarms, function consistently and are not disadvantaged in any way. See to it that your faculty knows about crisis ways out, signage, and how to use all crisis means. Awareness can do an outstanding bargain when it comes to lessening the endangerment of accidents.

6. Routine Inquiry

It’s human instinct that we, as a whole, have gotten self-satisfied after some time about specific things. That is the reason, significantly, you frequently assess your storage warehouse center for any likely issues. Routine investigations give you the reality to glance around and see what may require adjusting. It’s anything but difficult to slip into lethargic propensities for not cleaning up just as in the past. It’s additionally feasible for particular security hardware to debase after some time, so this is the perfect chance to look at it and repair it whenever required.

Inquiries are likewise the ideal opportunity to check whether your storage warehouse is advancing after some time. Does your business need development? At that point, your assurance systems may likewise be invigorated to purvey for how your warehouse is operated. Adjustment and advancement are vital for a flourishing business.

7. Correspondence

Training or qualifying is a significant percentage of running a protected stockpiling warehouse center condition, yet so is compelling correspondence among you and your pickers. This can cover numerous circumstances. Monitoring the development of stock or revamping a region of the storage warehouse should include a lot of correspondence. Be that as it may, it can likewise be as straightforward as guaranteeing that everybody knows precisely what’s happening at some random time. Best shoes for warehouse workers should be advised to wear by the pickers.

Correspondence is likewise key for making everybody feel esteemed and comprehend what their job is inside the work environment.

The Bottom Line

Your storage warehouse needs to place security first above everything else. Contrarily, working environment accidents mean rest, doctor’s visit expenses, administrative protection work, lawful risk, and laborers’ pay issues for your business. This must mean a drop in profitability and resolve. Limit these mishaps by adopting a proactive strategy to address these mentioned tips for security improvement.