IQF technology is the best method of delivering high-quality, premium-grade products onto the market in record time nowadays. The secret lies in a dozen unique factors that mesh to create an efficient, lucrative working medium that has many cost-saving elements. Finding the right approach to work for your business requires a thorough analysis of both the advantages and disadvantages of this technology – something this article looks to provide.

Take advantage of the rising worldwide popularity of frozen food, and nutritious, appealing IQF food, today – and build your food empire tomorrow. Here’s all you need to know.

Advantage: Reduced processing costs

Any business out there lives and dies by their profit margin. Barring excellent investment strategies that look to choke out the competition, this is the path taken by most enterprises. That makes saving costs and reducing expenditures especially important to see your business take off as soon as possible, and pay off the investments. Profitability, at the small and medium levels, keeps being the key factor of success. IQF helps you achieve it. The reasoning is threefold:

- Reduced labor costs – the highly-automated processing of food, creates a reduced need for personnel. There is less need for handling the food manually, or for general equipment maintenance (barring equipment-related).

- High quality – premium quality sells at a premium price. Today’s consumers are increasingly more picky when it comes to the quality of their food and processors work hard to meet those expectations. A more efficient equipment might mean a higher investment but in the long run it guarantees a much better ROI due to the higher selling price of the high-quality product which is so in-demand today.

- Faster processing speed – simply put, the food will freeze faster. That means that the necessary steps involved during the process are shorter, and generally require fewer resources over time.

Disadvantage: High up-front costs

As with any business endeavor, creating IQF products isn’t going to be cheap. Especially, given the premium grade of the product will require investing in technology and equipment that can consistently reach that level of quality. That means that the first investment into setting up such a processing line or the entire operation from scratch can be an obstacle for the unprepared.

Fortunately, there are ways around that. For instance, many companies will let you buy just the IQF Freezer and integrate it into a different processing line. While a complete processing line would be best to start with, as it was manufactured to work best as a set, you will find that most features of the Freezers still are in full force. Moreover, some equipment manufacturers offer attractive financing solutions for companies that struggle with the initial investment.

Advantage: Peak food quality

When looking to produce a qualitative, palatable product, there’s no better solution for most food choices than IQF. The individual quick-freezing approach inhibits the creation of large water crystals that are inevitably created by freezing the moisture inside the product. Unlike slower freezing methods, which would let the ice crystals grow bigger – big enough to damage cellular walls – the IQF approach doesn’t. That makes all the difference, as damaging the cellular walls is what prevents food from keeping its natural appearance.

In other words, food stored after IQF processing will look and taste better and be more nutritious than other types of frozen food. Keep all the nutrients, minerals, vitamins, and other valuable substances inside the food for the longest possible time with IQF. Not only does this help with nutrition value, something most customers would happily benefit from, but it also keeps the appearance, texture, and overall color of the product largely the same.

As a result, you’re producing something more delicious, visually appealing, and healthy than the competition can offer.

Disadvantage: Moisture can be an issue with less efficient equipment

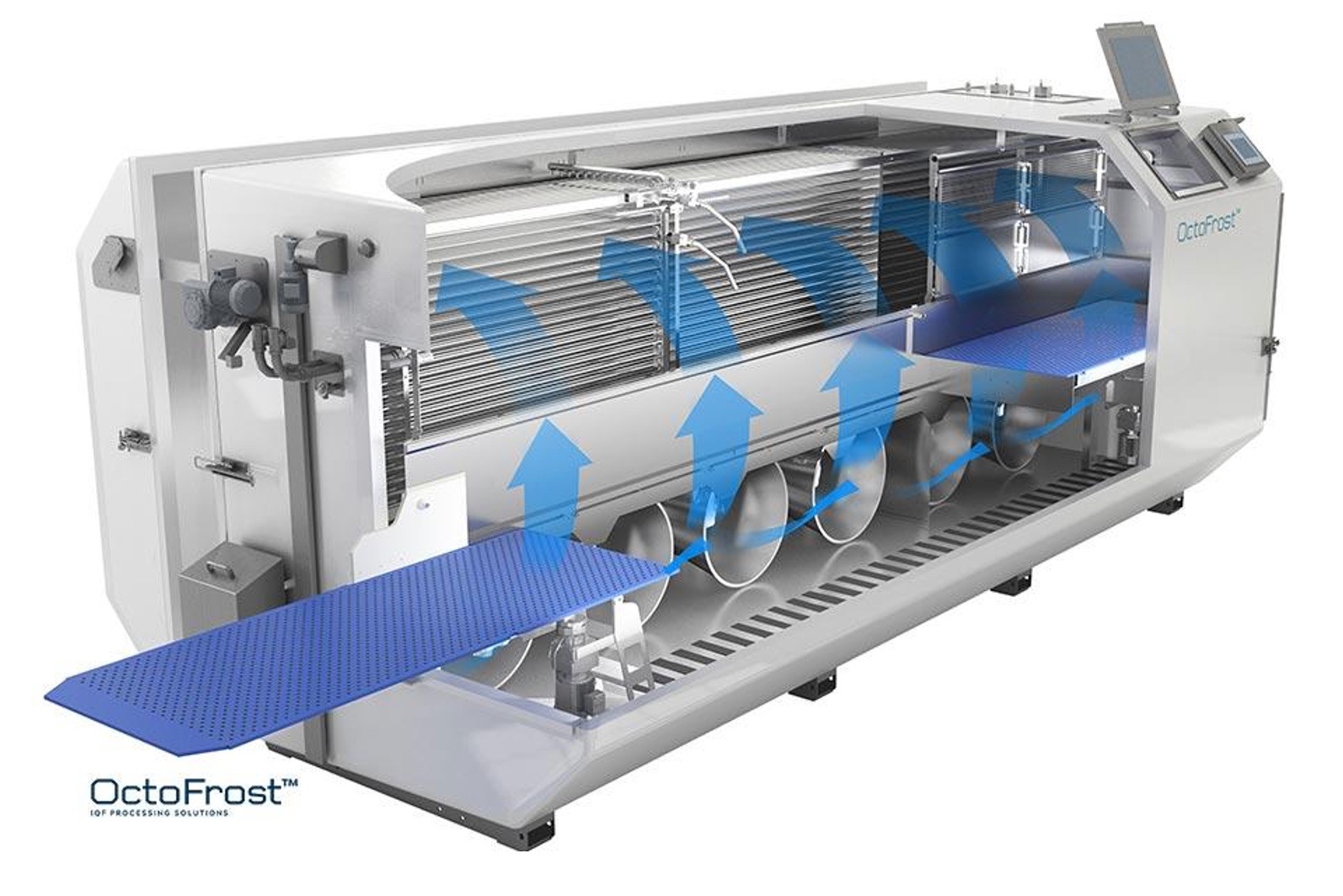

Frosting can be a problem when using a less efficient IQF freezer. The moisture included as a natural part of the food, can create frosting over the surface of the food and inside the freezer, if the airflow is not optimal. That causes the food to dry, damages its appeal, and might even affect its taste. Additionally, lost moisture inside the freezer, also called product dehydration – equals lost product weight and therefore less product to be sold.

This happens due to the moisture emanating in the form of water vapor during the freezing sticking to the product and creating a coating that will then freeze. However, there is a relatively simple approach that will work wonders for solving this issue: right airflow speed inside the freezer. A continuous and fast airflow of cold air, will keep the product dehydration to the absolute minimum.

Advantage: Safer, more sustainable food

When it comes to IQF freezing technology, it can be seen as a significant step towards a more sustainable future. Not only does it create frozen food of higher quality, and keeps more of its nutrients, but it also does so at an advantage for the producer.

When processing something sensitive, of higher value or more challenging, such as shrimp, efficiency and food safety are the core elements to focus on. With the wrong equipment, some parts of the shrimp will be undercooked or overcooked, while an efficient, smart machinery will take these risks to zero.

Certain excellent IQF processing lines will even have multiple temperature zones to choose from as part of their cooking phase, giving you further control over the quality of the product.

Finally, it also creates products with better food safety. Every single machine except OctoFrost is using belts nowadays. The best approach on the market is bedplate technology that makes maintenance and replacing the plates less of a chore, and more of a natural course of events. The best part is that it doesn’t require you to stop production at all, being faster and offering an industry-leading food safety rating in the process.