What is 3D printing? How does it work? And what can you do with it? This blog post will answer all of your questions about 3D printing.

We’ll also show you some amazing examples of what this technology can create. So, if you’re curious about 3D printing, stay tuned and read on.

Quick History of 3D Printers

The first 3D printer was created in 1984 by Chuck Hull of 3D Systems. He patented the process of stereolithography, which uses lasers to cure liquid resin into a solid object.

In the early days of 3D printing, the technology was expensive and only used by industrial manufacturers. However, the cost of 3D printers has come down over time, and they are now available to consumers.

CAD software plays a crucial role in 3D printing by facilitating the design and preparation of 3D models for printing. CAD software allows users to create detailed 3D models of objects. This is essential for designing the part or product you intend to 3D print. CAD software provides tools for creating complex geometric shapes, manipulating dimensions, and visualizing the final product. CAD software ensures that your 3D models are precise and accurate. You can specify measurements down to fractions of a millimeter, which is crucial for creating parts that fit together correctly or meet specific tolerances.

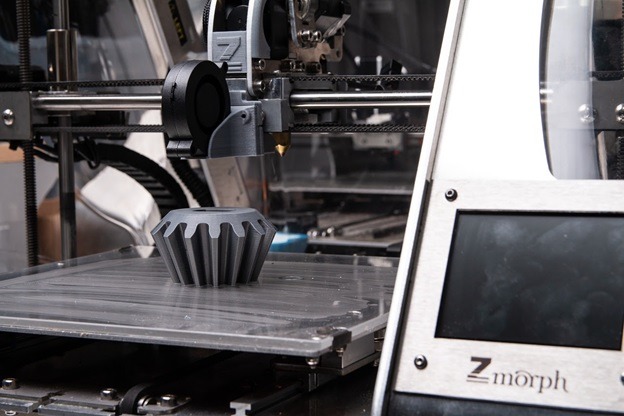

How Does 3D Printing Work?

3D printing works by creating a digital model of an object. This model is then sliced into thin layers and converted into a series of instructions that the printer can understand.

The printer then lays down these instructions one layer to create the object. For example, the printer will print the first layer using a thin line of plastic resin.

After this layer is complete, it will be washed away, and it will print the second layer on top of it. This process will continue until completing the final object.

3D Printing vs. Traditional Manufacturing

The biggest difference between 3D printing and other manufacturing processes is that 3D printing doesn’t require tooling or molds to create an object.

In traditional manufacturing, you can build objects by carving them out of a large block of material.

The disadvantage with this process is that you need to have a physical model before you can begin creating anything, making it hard for designers to test their ideas quickly and cheaply before a prototype.

With 3D printing, there are no such limitations. You can create a digital model of an object in minutes and then print it out using a 3D printer.

The other big advantage of 3D printing is that you can create complex shapes that would be difficult or impossible to make with traditional manufacturing techniques. This is because 3D printing doesn’t require any special tools or molds – the printer just prints whatever you tell it to.

The Most Basic Type of 3D Printer

There are several different 3D printers, but they all rely on the same basic principles. The most basic type of 3D printer is the desktop FDM printer. These printers use thermoplastic filaments to create objects.

The filament is heated and then extruded through a nozzle, depositing it on the build platform. Whenever the platform deposits a new layer, it moves down-which creates a three-dimensional object.

3D printing has come a long way in the past few years. It’s gone from being a niche technology used by hobbyists and industrial designers to becoming something everyone can use.

Today, there are dozens of different 3D printers available for consumers, and the range of objects you can create with them is endless.

Many countries are manufacturing 3D printers with their popularity today, such as China. If you’d like to know more about it, you can simply source it by searching the keyphrase sourcing agent China.

Where can you purchase 3D Printers?

There are many places to purchase 3D printers. The most popular online stores are Amazon and eBay. You can also find them at local electronics stores, or you can buy them directly from the manufacturer’s website.

How Much Do 3D Printers Cost?

The cost of 3D printers varies depending on the type and size of the printer. Desktop FDM printers typically cost between $200 and $1,000. However, there are also high-end printers that can cost several thousand dollars.

What can you make with a 3D printer?

Well, to be honest, the list is endless, but here are a few examples:

- Household items such as lamps, vases, and utensils

- Medical devices such as prosthetic body parts and surgical tools

- Jewelry such as rings, necklaces, and earrings

- Gift Boxes such as a customized perfume box

- Toys such as action figures and dolls

- Vehicles such as cars and drones

- Architectural models and decorations

- Industrial prototypes and parts for machines such as a jar capping machine

- Artistic sculptures and decorative objects

What’s even more exciting about 3D printing is its endless possibilities. Thanks to a new technology called continuous liquid interface production (CLIP), printing moving parts is possible.

In other words, if you can imagine it, the chances are that you can create it with 3D printing.

In addition to creating all kinds of objects from home, there are also several benefits to using a 3D printer instead of going out and buying one.

Once you have the printer itself, the cost of manufacturing an item is zero. You just need to buy the filament, which is relatively cheap. In addition, there’s no need to go to a store and wait in line for your item.

You can also enjoy using 3D printers at your home due to the endless stuff that you can build with it. Just place an order, and it will be delivered right to your doorstep within a few days.

3D Printing Service: Is It Worth It

A 3D printing service can be useful to you if you need 3D printing or elements of 3D printing but do not own a 3D printer. They can be great if you just need to get a prototype printed or even an initial batch of products to show investors. A quality 3D printing service will be able to deliver a good standard of workmanship at an affordable price. They’ll also be able to work with numerous materials, these can include:

- Nylon

- Plastics

- Metals

- Wood

If you find a good 3D printing service it’s certainly worth it because you get all of the benefit of a top-of-the-line 3D printer without having to pay for one, or pay for the ongoing maintenance. If you’ve got a project in mind, big or small, always consider 3D printing as an option…it can be a lot cheaper than other manufacturing options out there and it can be surprisingly cheap. The key is in finding a good business to work with.

Conclusion

In case you’re wondering, 3D printing isn’t going anywhere anytime soon.

We think it’s an incredible tool that allows anyone with a computer and an idea to turn their dreams into reality, all they have to do is create a digital file and let the machine take over.