If we think about the greatest inventions of human history, it is not unreasonable to state that the inventions related to modern technology are some of the most important we have ever come across. Its right up there with inventions like the Phonautograph by Édouard-Léon Scott de Martinville. From calculators to massive internet infrastructures, the age of computers has well and truly changed our life for better and for worse. One relatively small invention in this timeline was that of a Printed Circuit Board (PCB). However, when we look at the history of PCB assembly and application, calling it a small invention almost feels criminal. Nowadays, PCBs are basically the standard for all electronic gadgets around us and its history gives us a good account of how something like the PCB came to be.

Military Use

Shrinkage of components like to be a theme in history of electronics. As time passes and technology progresses, gadgets lose their size and multiply in functionality. Similarly, the predecessor for PCBs also used to be ‘Point to Point’ construction mechanisms. They were bulky as well as largely unsafe, and ultimately removed from daily usage with PCB’s invention. In 1936, shortly before the beginning of the Second World War, an Austrian engineer, Paul Eisler invented the PCB while working on his radio. Along with this, the technology, once developed in England by Eisler, was not used for some time. In fact, it was World War 2 where the new innovation was truly put to use. Around 1943, the US armed forces brought Eisler’s invention to the frontline when they used it in the proximity fuses.

Public use and constant reiteration

In 1948, with the war ending, USA started this invention for commercial use. However, it took until the 50s for a technology like this to be commonplace within the public. Even still, the trend of technology getting more and more compact continued for PCB. Originally, it was in a very crude state. It is fascinating to know that fully wired components as well as drill holes do not scream of a modern piece of technology. Indeed, the types of PCB found in the war were very different from the little chips we find in our everyday electronics. As mentioned before, they were fully wired with holes drilled. However, these wires were passed through the holes. These were connected to the PCB. This improved as more research showed up in the field. In this way, the PCB was finally becoming more compact and consumer friendly. These were all, of course, attempts to not only improve the PCB, but also to make them more profitable in the consumer market. The objective of making them consumer friendly was achieved by the 50s. however, with the introduction of the Auto-assembly process, there is a great need to know that the printed circuits for the PCB were known as common sight in consumer markets.

Indeed, iteration does not stop at one milestone. For tech markets, iteration is also the key to attracting more customers. Less cost and better performance is always the goal. For the PCB, improvement was on the way. Board lamination technology as well as etching techniques were also a breakthrough for the PCB’s further development. Soldering was now made easier as it can also be done automatically.

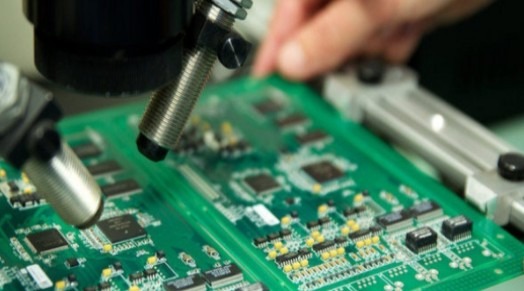

It was done in a wave-soldering machine, this was still not enough. More iteration was done with more outstanding results. Bear in mind that moving away from through-hole components, small mounts became the new normal in PCB assembly. Smaller boards became the norm in the market.

This resulted in several benefits, including better performance with lower costs. However, this also meant that repairing faulty boards also became bigger headache since everything was so compact. Overall, it is important to understand that modern technology is an ever-evolving field, and it would not be unreasonable to expect more iterations in technology like this.