It isn’t hard to see why businesses in the manufacturing industry continue to flourish and thrive. Beyond aiding in innovation, research and development, the sector also aids in the extermination of poverty and unemployment and helps in elevating the economic growth of a country. It is for this reason that it remains a popular venture for many entrepreneurs.

However, establishing an enterprise in this sector isn’t cheap. In reality, it is an expensive endeavor, with all the raw materials, equipment, and labor that it requires. If you fail to keep your costs under control, you will not only save yourself from generating enough revenue to sustain your operations. But you may even incur financial stress and losses. With that in mind, here are a few ways to run your manufacturing facility cost-effectively.

Practice lean manufacturing

A methodology that prioritizes waste minimization while maximizing operational productivity at the same time, practicing lean manufacturing can help you keep expenditures low without compromising the quality of your offerings. As a business owner, you must focus your efforts on the elements that give you value. It would help if you also found specialists who can dispose of your factory’s waste in an environmentally friendly way. For instance, if your facility is located in Kansas City, there are several options for scrap yards in Kansas City that can take care of your scrap metal like aluminum and cast iron for you. Since waste is something that very few, if no one, would pay for, it makes sense to find ways to reduce it by thoroughly assessing your existing processes and eliminating non-essentials. You’ll improve the efficiency of the manufacturing facility and lessen wastage simultaneously.

Prioritization of your ROI

Manufacturing plants can only succeed if their owners are keen on what they’re willing to invest and have realistic expectations on the revenue that it’s likely to generate. So before you make any financial commitments, you need to understand and prioritize your ROI or return on investment. Many inexperienced entrepreneurs tend to overlook having comprehensive audits, thinking that the task demands a lot of time and effort. However, doing so will allow you to get the numbers right, and as a result, maximize the profit potential of your business.

Common Misconceptions in Manufacturing Business

Manufacturing is integral to the global economy, producing goods essential to our daily lives. Manufacturing plays a vital role in shaping the world, from the clothes we wear to the cars we drive. It includes various activities, such as raw material production, component manufacturing, and final product assembly. The industry manufactures everything from consumer electronics to high-tech medical devices and employs millions worldwide. As vital as it sounds, there are myths around the manufacturing industry. Let’s identify some of them.

1. Manufacturing is for the boys

Manufacturing offers many great career opportunities for women. From hands-on production to management positions, women can find exciting and rewarding jobs with high-paying potential at all levels of manufacturing. This type of industry encompasses various activities such as designing, producing, and delivering genderless products. While the manufacturing industry may not be inherently gendered, there are still significant gender disparities.

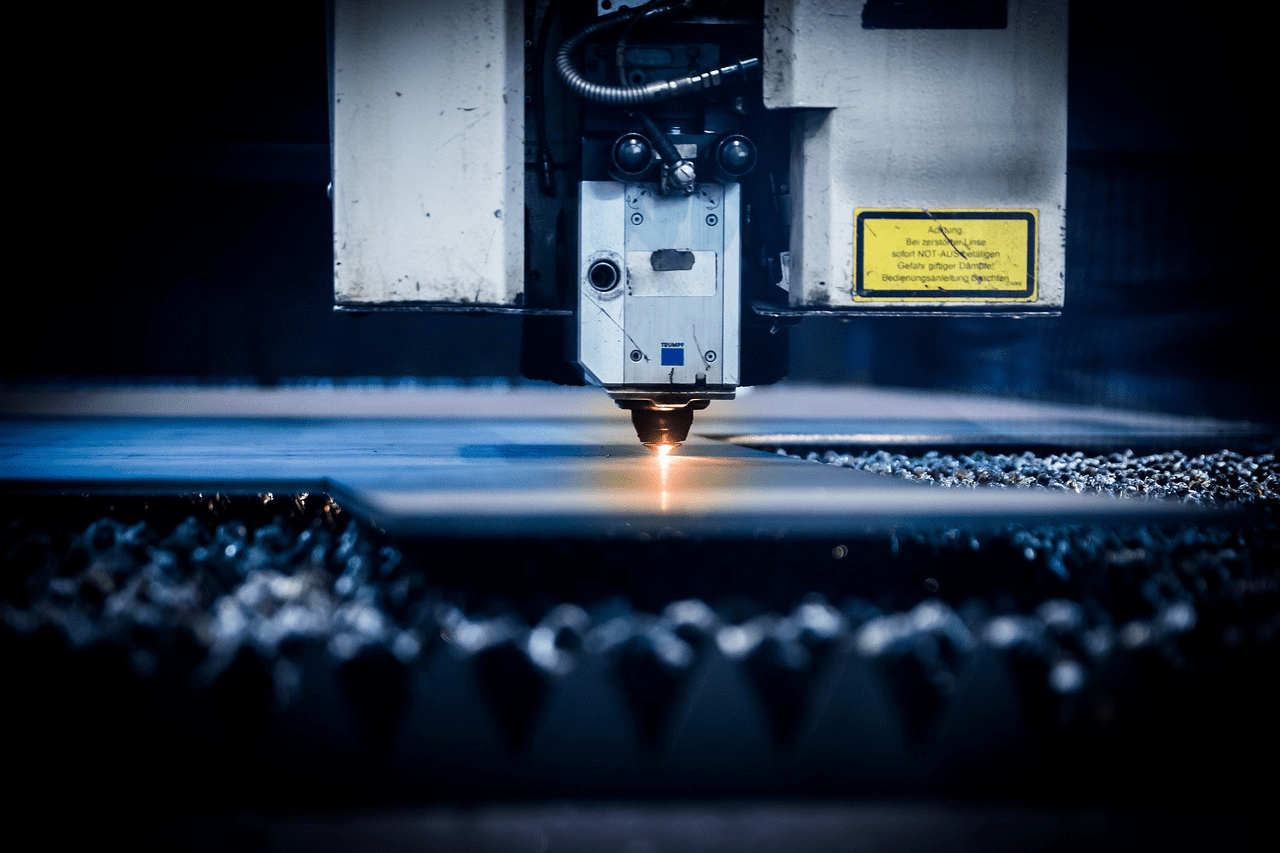

2. Manufacturing is dangerous and dirty

One of the primary benefits of the manufacturing industry is that it creates jobs and drives economic growth. In addition, the manufacturing industry often provides well-paying jobs that require specialized skills, such as engineering or technical expertise. However, it has been stigmatized that heavy labor is always needed in the manufacturing industry. It may have been good years ago when manufacturing workplace conditions needed improvement and posed health risks to employees. Now, manufacturing facilities are clean and safe with high-tech machinery and workplace standards that protect the well-being of employees. Many manufacturers are turning to automation and other technological innovations to streamline operations and remain competitive in the global market.

3. Manufacturing industry is for low-skilled workers

As the demand for goods and services grows, manufacturing will remain a key driver of innovation, job creation, and economic growth. Achieving success in this work sector requires ongoing education and hands-on training. Employers seek well-rounded, quick-thinking individuals who can work well with others. Critical thinking, innovation, and teamwork are essential in today’s manufacturing job market.

4. Manufacturing jobs pay less

Manufacturing is a massive industry with many different professions. Also, manufacturing workers are more likely to benefit better than other industries. Employers today invest time and resources in talent development and training to help employees advance, increasing compensation. Like many other industries, manufacturing relies on a diverse network of employees across different departments to thrive. From clerical work to the manufacturing industry, there is a place for everyone to play an active role in manufacturing with better leverage on salary.

Find ways to reduce energy consumption

Energy consumption takes up a sizable portion of a manufacturing plant’s expenses. If you want to drive down your fixed costs significantly, you must find ways to reduce its energy use. From utilizing energy-efficient equipment and investing in new HVAC systems to the incorporation of clean and renewable energy sources, any investments made in keeping the consumption of energy at a minimum will pay dividends in lowering your business costs and increasing its profit margins.

Despite the lucrative nature of a manufacturing enterprise, it can be a costly business pursuit too. However, by focusing on the ROI, adopting lean manufacturing practices, and keeping the manufacturing facility’s energy consumption down, you’ll maximize your opportunities for financial stability and growth.