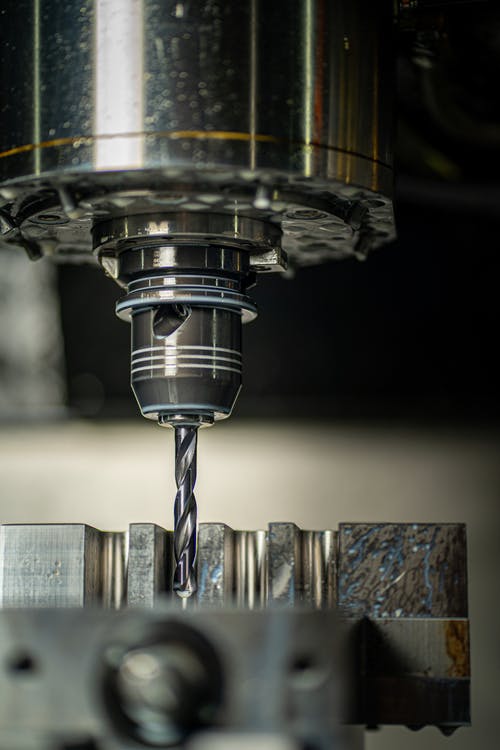

CNC machines are one of the most common tools used to manufacture products. CNC stands for computer numerical control, which means the machine tool used to work on a material is being controlled by a computer program rather than an operator. A CNC milling machine uses spindles that are rotating at extremely high speeds to remove material from the surface of the workpiece.

What is CNC Milling?

CNC milling is a specific type of computer-aided machining (CAM) and needs to be distinguished from CNC turning, which uses similar technology but applies it to rotating workpieces.

CNC milling allows the machine head to move in three dimensions rather than just two, as in conventional milling machines. The result is much more complex workpieces, both smaller and more accurate than with traditional milling.

Different CNC mills exist. Some machine heads can move along three axes (X-Y-Z), while others are designed for movement along two axes (usually X-Y). Also called “2.5D” or “two and a half dimensional” machining.

What are they used for?

While expensive, CNC mills are highly versatile and can produce custom CNC machining parts that would otherwise be impossible with other manufacturing technologies. One example is the ability to machine features extending up to +/- 20mm from a part’s surface in one pass by using wide tools. They are so versatile; they are routinely used for making molds for casting.

CNC mills are also used for engraving and metal spinning.

In the future, CNC milling will be increasingly important because of their ability to replace today’s mass-production machines in the automotive industry.

Here is why:

Traditional machine tools have a set injection time of one part per hour or even less, but an individual CNC mill can machine an entire car body in one run.

CNC milling is ideal for prototyping, because the time to make a part does not vary with its complexity. Even if it takes 30 hours to machine, you know that this time will be multiplied by the number of identical parts required – so where other processes are non-deterministic, CNC milling is essentially deterministic.

CNC milling can produce shapes and details which cannot be produced by traditional machine tools. It is extremely accurate and ideal for mold-making and prototyping, as well as creating serious amounts of waste material with very little effort.

Industries that use CNC milling

The industries using CNC milling include medical, aerospace, automotive, consumer electronics and even firearms.

CNC milling is also used to create dies which are used in cold forming, which can produce complex metal parts with ease. These shapes cannot be reproduced by traditional die casting techniques.

The Medical Industry

In the medical industry, CNC milling is used to create prosthetics and implants. This is one of the most demanding applications for a machine tool, as it needs to be highly accurate, precise, and durable.

While a computer-controlled machine can offer high accuracy, operating a machine of this kind is also a precise art. The idea of CNC milling is to make tools which are used in creating physical objects, where precision is key. This makes it even more important that the operator controls the machine to within fractions of a millimeter.

Aerospace industry

Another demanding application for CNC milling is with the aerospace industry. They need parts which are lightweight, yet durable enough to withstand high temperatures when flying at high altitudes.

The key here is in the material itself. Since CNC milling often uses metals, like aluminum and titanium, using these materials will reduce the weight of a part while still making it durable.

Automotive Industry

A CNC milling machine is particularly good at creating small details of a structure, making it great for the automotive industry.

Firearms Manufacturing

One of the most dangerous and demanding applications for a CNC milling machine is in firearms manufacturing. Firearms can be dangerous under certain conditions, which means that every single part has to be manufactured precisely.

In addition, milling machines are often used when creating firearm parts from scratch, such as an entirely new structure or mechanism. They are also used to modify existing parts, such as modifying a trigger or changing a barrel.

Modern manufacturing

CNC milling can be used for advanced manufacturing purposes as well. Fabricators, mold makers, and other people and companies related to advanced manufacturing usually use CNC mills.

For example, a fabricator using the CNC milling technique will be able to create an incredibly complex mold or device with just one machine. This is done by setting up multiple tools as well as nesting them on each other.

Conclusion

CNC milling can be used for many purposes. It is especially useful in the high-tech industry, as it helps fabricators create complex molds and devices. CNC milling can also manufacture or change parts – even expert carpenters use it sometimes!

Thanks for reading!