Thrashing your ATV at full throttle through all sorts of terrain is the main reason you got one in the first place. It’s just all part of the fun. And this lasts longer with regular upkeep. You’ll be changing out common replacement parts, like drive belts, CV boots, and axles to keep machines churning out all the power and thrills when and where you need them.

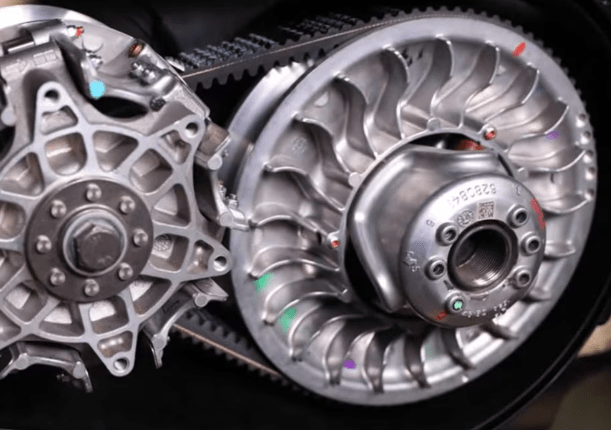

Feeding that power from the engine to the wheels in most ATVs and UTVs is a Constant Variable transmission, or CVT. It consists of two sets of pulleys, connected by a drive belt. It’s simple in operation and allows powersports machines to maintain optimal engine revs and power at all times. CVTs do this by constantly changing gear ratios depending on engine loads.

While belts are built tough, the high engine torque, extreme tension, and heat acting on the belts as pulleys move closer or further apart, are the main reasons they go bad. The good news is that an ATV drive belt is relatively easy to swap out. All it takes is the right replacement belt, a few basic tools, and knowing your machine.

Belt Basics

1000-cc machines can put out over 150 hp and truckloads of torque. Throw in the heavier weight of regular UTVs and sports ATVs, and the loads acting on belts to get that power to the wheels, and you can see why they’re some of the first parts that need replacing.

Belts face extreme force, especially on the sidewalls, as clutches squeeze them through the pulleys to reduce acceleration. At the same time, they’re spinning close to 10000 rpm and engaging the secondary clutch to efficiently distribute engine power through the drive axles and wheels. Lastly, add heat nearing 200 F, and you get the recipe to smoke the belt to pieces.

Why Drive Belts Go Bad

At some point, belts need to be changed. They can last anywhere between a couple of miles to a few thousand miles, and this depends on a few key factors:

- How you drive – being harder on the throttle, and going through the machine’s entire rev range within seconds is the easy way to tear the belt in two. Demanding applications are especially tough on the aramid, carbon or Kevlar-reinforced core that holds the different body compounds and cover materials together.

- High engine loads – related to high revs are high torque numbers. High loads can shred belts to pieces, particularly in abrupt uses of full throttle to get the machine over tougher terrain.

- Not using low gear when you need to – use low gear when steadily negotiating inclines, during rock crawling, pulling heavier loads, and general slow-speed driving. This means the required RPMs for the load and a belt that’s precisely aligned to the clutch sheaves. Using high gearing in such cases not only stresses the engine but can also snap or burn the belt.

- Skipping Maintenance – inspecting belts for uneven wear, bad or worn teeth, fraying or chipped edges, and broken cords or cracks should be done regularly, before and after rides. Any of these signs means you’re already losing performance when it matters or there are issues with the clutch itself. Uneven wear on the ATV drive belt points to misaligned clutches.

- Where you drive – seals on clutch covers and the belt intake and outlet ducts can accumulate dust, debris, mud, and water. Unplug the drain plug and clear the water, or remove the clutch cover and douse the area with some clean compressed air.

Choosing Replacements

Transmission belt manufacturers make a range of drive belts suited to different types of vehicles. This takes into account engine displacement, power output, and vehicle weight. Belts are also classified by durability and the type of driving you do into medium, heavy-duty, and severe-duty variants. The wide range additionally means there are quite a few upgrade options and belts in different price brackets. Before buying your next ATV drive belt, here are a few key considerations:

Compatibility

Knowing the ins and outs of your ATV or side-by-side means you’re well aware of which belt is right and which isn’t. Go with parts and vehicle numbers to ensure no fitment issues. Belts must be of the exact size, meaning length, and width, as well as have the right tooth count, arrangement, and type to fit the clutch pulleys. You also need to observe the power ratings the belts can handle. One common mistake is cheapening out on lower-rated belts used on machines with a lot of grunts. You’ll not only smoke the belt in minutes but also risk damage to the transmission and engine.

How You Ride

As mentioned, belt makers have more than one belt for any single machine. This means some belts are tuned for longevity, while others may not last as long, but wring out the last few horsepower the engine has in reserve. Your riding style will dictate which one you choose. Casual ATV and UTV riders should stick with standard offerings, as these are still built tough enough to handle a bit of fun on the side. But if you’re racing or going full-out on the throttle, then a high-performance belt made to endure tension, and heat, and efficiently transfer engine loads is definitely a better buy.

Materials and Build

The choice of materials that go in the different belt layers determines among other things how belts handle varying temperatures, transitions from low to high revs, high shock loadings, excess weight and contaminants such as oil, water, and dirt. Too much of any of these factors leads to clutch slippage, advanced belt wear, gradual or abrupt loss of power, and eventually, the belt ending up in pieces.

The central tensile cords are the main load-bearing elements, and here materials vary from polyester seen in standard-use belts to Kevlar (or other aramids) and carbon fibre in high-performance variants. Body compound materials making up the synthetic rubber layers below and above the cords range from chloroprene to extra durable ethylene or diene rubber composites. Ethylene belts perform particularly well under higher temperatures and engine loads, so should resist hardening or cracking. An additional top fabric layer is seen on some performance belts, and this deals with engine oil and dirt and further reduces possible wear. Generally, the more belt makers have invested in quality materials, the longer the belts will last.

OEM or Aftermarket?

OEM belts in some ATV and UTV makes are high-performance and long-lasting. They easily get to the quoted mileage while being pushed hard. However, replacements are super pricey, and if you like aggressive driving through tough terrain, then you’ll also need a spare or two, just in case.

Aftermarket ATV and UTV drive belts offer a few benefits. They’re cheaper, come in variants suited to different riding styles, and are still built to high standards. Dozens of belt makers churn out quite a few belt lineups, so there’s something for both casual ATV enthusiasts and anyone looking for the best performance in a belt that lasts.