Researchers at Trinity College Dublin, led by Dr. Susan Flavin, spent three years recreating 16th-century household beers to study their strength and nutritional value. The study highlighted the importance of ale and beer in the early modern diet.

Earlier studies suggested that rural men drank about four pints of beer daily, while skilled stonemasons working for the Church received up to 15 pints as part of their pay.

Historians previously believed that beer back then was weaker than today’s. However, Dr. Flavin’s interdisciplinary study aimed to recreate 16th-century Irish beers to better understand their actual strength and the spirit of people at that time.

Brewing beer in the 16th century was an art that combined traditional methods and natural ingredients. Here’s a step-by-step look at how beer was made during this time, along with some interesting facts and figures.

Ingredients Used

In the 16th century, beer was crafted using essential ingredients such as water, malt, yeast, and hops. This period saw significant advancements in brewing, notably with the introduction of hops, a Dutch innovation that transformed the process. Hops not only imparted bitterness to balance the malt’s sweetness but also served as a natural preservative, improving both the beer’s flavor and shelf life.

The basic ingredients for brewing beer in the 16th century were:

- Water

- Malted Barley

- Hops

- Yeast (wild yeast, naturally occurring)

Malt, made from barley, added sweetness to the beer. Brewers chose specific types of barley for the best flavor. Water was also carefully selected to ensure it didn’t affect the beer’s taste. In addition, yeast also played a key role in fermentation, turning sugars into alcohol and carbon dioxide, giving beer its fizz and strength.

During this period, sourcing heritage ingredients like landrace cereals posed challenges due to variations in quality and availability. These traditional cereals were crucial to maintaining the authentic taste of the brew. The entire brewing process relied heavily on these components, reflecting the intricate balance and knowledge that brewers had to master.

Brewing Process

- Malting

The malting process began by soaking barley in water to start germination, which was crucial for creating the sugars needed for brewing beer. This process converted the starches in the barley into fermentable sugars.

Brewers need to be skillful to carefully monitor the germination to ensure the barley grew just right. Over-germination could ruin the batch of beer.

Once the barley sprouted enough, it was dried in a kiln, a special oven that controlled the heat. This drying stopped the germination and preserved the sugars.

The kiln was vital for ensuring the quality of the malt. Proper drying turned the barley into a stable form, ready for brewing.

- Mashing

- The dried malted barley was crushed and mixed with hot water in a large vat called a mash tun. This created a thick porridge-like mixture known as the mash.

- The heat activated enzymes in the malt, converting more starches into sugars. This sugary liquid was called wort.

- Boiling

- The wort was transferred to a large cauldron or kettle and boiled. During this boiling process, hops were added.

- Hops: These flowers added bitterness to balance the sweetness of the malt and acted as a natural preservative.

- Fermentation

- After boiling, the wort was cooled and transferred to fermentation vessels, typically large wooden barrels.

- Yeast: Natural wild yeasts in the environment would ferment the sugars in the wort, producing alcohol and carbon dioxide. This fermentation process could take several days to weeks.

Without modern temperature control, this resulted in different flavor profiles and alcohol content.

Yeast strains were a mix of wild yeasts, making each batch unique and unpredictable. Some batches tasted great with good alcohol content, while others were off-tasting, too weak, or too strong.

These inconsistencies were both a charm and a challenge for brewers. They relied on experience and intuition to manage fermentation and produce the best beer possible.

Despite the difficulties, using natural yeasts and open fermentation created brewing traditions that continue to evolve today, giving each brew a distinct character.

- Maturation

Once fermentation was complete, the beer was transferred to large wooden barrels for the maturation process. This stage allowed the beer to age, which was crucial for developing its flavors and ensuring a smoother taste.

During maturation, the beer’s complex flavors and aromas matured and evolved. The interaction between the beer and the wooden barrels added subtle nuances to the flavor profile, contributing to the unique character of each batch.

Maturation also allowed time for impurities and sediment to settle at the bottom of the barrels. This natural clarification process improved the beer’s clarity and overall quality.

Brewers carefully monitored the aging beer, sometimes making adjustments as needed. They relied on their experience and intuition to determine the optimal maturation period, which could range from a few weeks to several months.

Before packaging, brewers conducted a final tasting to ensure the beer met their standards for flavor, aroma, and consistency. Any adjustments were made during this stage to perfect the brew.

- Packaging

Transferring to Smaller Barrels: After the maturation process, the beer was carefully siphoned off into smaller barrels or casks. This transfer required skill to avoid disturbing the settled impurities and to maintain the beer’s clarity and quality.

Cask Preparation: The smaller barrels, typically made of oak, were prepared and cleaned thoroughly before use. Proper preparation of the casks was essential to prevent contamination and ensure the beer remained fresh.

Sealing and Storage: Once filled, the casks were sealed tightly to preserve the beer’s freshness and prevent spoilage. Wax or pitch was often used to seal the barrels, creating an airtight environment.

Labeling and Identification: Brewers often marked the barrels with specific symbols or labels to identify the type of beer and its brewing date. This helped in managing the inventory and ensuring the beer was consumed in the optimal order.

Transporting the Beer: The filled casks were then transported to taverns, inns, and other locations for consumption. Transportation methods included horse-drawn carts and ships, depending on the destination. Care was taken to handle the casks gently to avoid agitation that could disturb the settled impurities.

Serving the Beer: In taverns and inns, beer was often served directly from the cask. Bartenders tapped the barrels to draw beer into mugs or pitchers, ensuring patrons received a fresh and flavorful drink.

Reusing Barrels: After the beer was consumed, the empty barrels were cleaned and often reused for the next batch. This practice was economical and sustainable, but it required meticulous cleaning to prevent contamination of the next brew.

The packaging process in the 1600s was crucial for maintaining the quality and flavor of the beer from the brewery to the consumer. Each step, from siphoning to sealing and transportation, was handled with care to ensure that the final product met the high standards of the time.

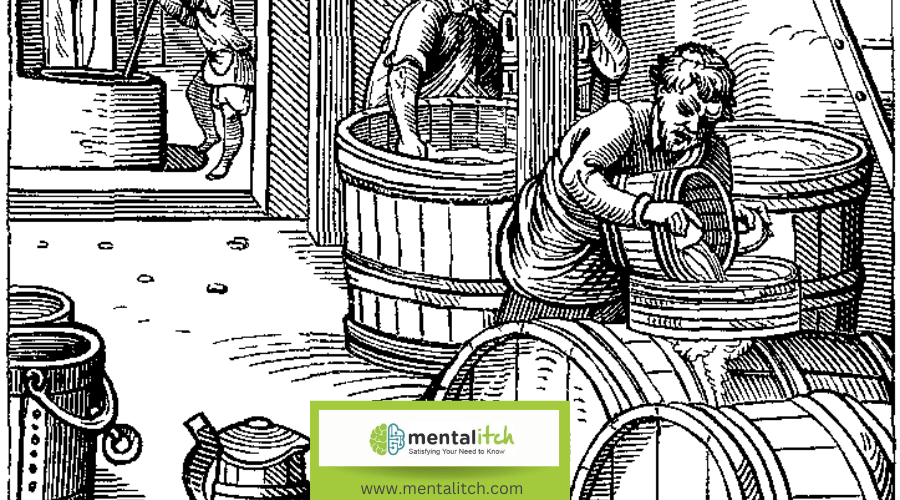

Brewing Equipment

The effectiveness of 16th-century brewing also depended heavily on the equipment used. Brewers employed various specialized tools to produce beer. Kettles were crucial for boiling the wort.

Wooden mash tuns were essential for mixing malted barley with hot water, extracting the necessary sugars for fermentation. After boiling, the wort was transferred to open fermentation vessels made of wood or metal which allowed yeast to naturally interact with the wort to start fermentation.

Though fermenting vessels varied in material and design, their primary purpose was to provide an environment conducive to yeast activity. Once fermentation was complete, the beer needed to be stored and transported, which is where barrels came into play. Storage barrels, often made of oak or other woods, held the beer and sometimes imparted additional flavors as it aged.

This careful selection of brewing equipment ensured that each step of the brewing process was executed efficiently, resulting in a quality beer.

Role of Hops

Hops played a crucial role in 16th-century beer production by imparting distinct flavors and serving as a natural preservative. Prior to the widespread use of hops, beer spoiled quickly and lacked the characteristic bitterness now commonly associated with it.

The use of hops also facilitated tax collection, as governments found it easier to regulate and tax beer containing hops compared to other brewing ingredients. Furthermore, hops reduced fire risks. Before their widespread adoption, brewers relied on herbs and spices, which required drying over open flames, thereby increasing the risk of accidental fires.

Hops were instrumental in the development of bottom-fermented beers, which ferment at cooler temperatures. The preservative qualities of hops allowed these beers to be stored longer and transported further, contributing to the shift toward large-scale production.

Interesting Facts and Figures

- Alcohol Content: Beers in the 16th century typically had a lower alcohol content than modern beers, often ranging from 2-4% ABV (Alcohol by Volume).

- Shelf Life: Without modern refrigeration, beer was best consumed fresh. Hops helped extend the shelf life, but it was still a perishable product.

- Brewing Centers: Monasteries were major brewing centers, known for their high-quality beer. Monks played a crucial role in refining brewing techniques.

- Women Brewers: Brewing was commonly done at home, and women, known as brewsters or alewives, were often responsible for brewing beer for their households.

Conclusion

Brewing beer in the 16th century was a labor-intensive process that relied on natural ingredients and traditional methods. While the equipment and techniques have evolved over the centuries, the basic principles of brewing have remained the same. This historical brewing process laid the foundation for the diverse and complex beers we enjoy today.