In the 17th century, beer production involved several meticulous steps. It began with the malting. The process included germinating and drying the barley to extract sugars essential for fermentation. Next was mashing the malted barley in hot water to further extract these sugars, followed by filtration using cloth and straw.

Boiling hops was then added to provide bitterness, aroma, and sterilization. Fermentation and aging in wooden kegs were the final stages, transforming the mixture into beer. Each step was vital to the quality and flavor of the final product.

Ingredients Used

Beer brewing during 1700s used basic ingredients like water, barley, hops, and sugar. Barley was the top choice because it was ideal at extracting sugars needed for fermentation. When malted, barley released these sugars in form of yeast then turned into alcohol, making barley the key ingredient in beer.

Hops were equally vital. They are added during the boiling stage and imparted bitterness to balance the sweetness from the malted barley. Additionally, hops contributed a distinct aroma and acted as a natural preservative, extending the beer’s shelf life.

Thus, the combination of water, malted barley, hops, and sugar formed the essential foundation of 17th-century beer.

Malting Process

When studying the malting process in the 17th century, start by understanding the criteria for selecting high-quality barley.

Grain Selection Criteria

Selecting the right grain, particularly barley, was crucial for brewing high-quality beer. Soaking barley in water initiates the transformation of starches into fermentable sugars, forming the foundation for a flavorful and well-fermented beer.

Brewers were meticulous about the quality of barley. The grain needed to be plump, disease-free, and uniform in size to ensure even malting. Monitoring temperature and moisture levels during malting was critical for optimal germination and sugar conversion. Any deviation could result in poor-quality malt, leading to inferior beer.

While barley was the staple, other grains like wheat and oats were occasionally used to create variations in taste and texture, but these were supplementary rather than primary ingredients. The emphasis on high-quality barley and precise malting techniques underscored the importance of this grain in producing excellent beer.

Germination and Drying

Brewers soaked barley in water to initiate germination, transforming starches into fermentable sugars. The soaked barley was then spread out on malting floors to germinate.

Once germination reached the desired point, brewers stopped it to preserve the sugars by drying the malted barley in kilns. This drying process was crucial because it not only stopped germination but also contributed to the development of flavors needed for brewing beer. Controlling the drying process required skill, as the heat levels had to be precise to achieve the desired malt flavor profile without burning the grains.

Malt Storage Techniques

After drying malted barley, store it properly to maintain its quality for brewing. Keep the dried malt in cool, dry conditions to prevent moisture re-entry, which can cause spoilage.

Store well-dried barley grains in breathable sacks, like burlap, to allow air circulation and keep the malt dry. Ensure storage areas are well-ventilated, cool, and pest-free, as rodents and insects can severely damage the barley. Secure the storage space.

Inspect frequently for signs of moisture, pests, or spoilage, and address any issues promptly to salvage the malt.

Properly stored, malt can remain usable for several months, ensuring high-quality beer brewing. Mastering these storage techniques is vital for maintaining the quality of the barley and ensuring a successful brewing process.

Mashing Technique

Brewers in the 17th century employed a mashing technique to extract essential sugars from malted barley, crucial for fermentation.

Here’s a concise breakdown of the process:

- Malted Barley Soak: Malted barley was steeped in hot water, not boiling, to break down starches into fermentable sugars. The temperature, typically around 150-160°F (65-71°C), was critical for optimal enzyme activity.

- Heating and Stirring: The mixture was heated and stirred continuously to ensure even extraction of sugars. Maintaining a consistent temperature was vital.

- Separation: After adequate soaking, the mash was filtered, usually through a vessel like a modified whiskey barrel, to separate the liquid wort from the spent grains.

- Boiling and Hops Addition: The collected wort was then boiled for about two hours. Hops were added during this phase to impart bitterness and act as a natural preservative.

Mastery of these steps allowed brewers to produce a beverage that was safer to drink than water and rich in flavor and tradition.

Filtration Methods

Brewers primarily used cloth and straw filters to separate solids from liquids in beer. They also utilized gravity-based separation to ensure a clear, impurity-free brew. This was crucial for producing quality beer ready for subsequent brewing stages.

Cloth and Straw Filters

Cloth filters, typically made from linen or cotton, played a crucial role in straining the mash and extracting the liquid, ensuring that finer particles were removed for a cleaner final product.

Straw filters were commonly used to separate the liquid wort from the spent grains. These filters excelled at trapping larger particles and sediment, allowing the liquid to pass through while retaining unwanted debris. By using straw filters, brewers could be confident that their beer had fewer impurities and a more refined taste.

Here’s how these methods worked:

- Cloth Filters: Used to strain the mash, separating liquid from finer particles.

- Straw Filters: Effective for removing larger particles and sediment.

- Smoother Beer: Both methods contributed to a clearer, smoother beer.

- Cleaner Product: Ensured the final product was free from unwanted debris.

Gravity-Based Separation

To separate the liquid, the mash was placed in barrels equipped with small holes or slits that allowed the liquid to seep through while retaining the grain.

Once the liquid was extracted, it was boiled for about 2 hours. During this boiling stage, hops were added to impart flavor and act as a preservative.

After boiling, the liquid was cooled and yeast was added to initiate fermentation. During fermentation, yeast converts sugars into alcohol and carbon dioxide, completing the brewing process.

Boiling and Hopping

Boiling the liquid with hops was a crucial step for the beer’s flavor and safety. Adding hops during the boiling process did more than infuse flavors; it acted as a natural preservative and sterilized the liquid, essential for a clean and safe final product.

- Flavor Extraction: Boiling extracted bitterness and aroma from hops, balancing the sweetness of the malt.

- Sterilization: Boiling killed unwanted bacteria and yeast, preventing spoilage.

- Preservation: Hops served as a natural preservative, extending the beer’s shelf life.

- Timing: The boiling typically lasted about two hours, allowing flavors to fully integrate.

Fermentation and Aging

Brewers added yeast to the mixture, which initiated the fermentation process. This critical stage lasted several days, during which the yeast converted sugars into alcohol and carbon dioxide. Maintaining the right balance of time and temperature was important for successful fermentation.

Following fermentation, the young beer underwent an aging process. Colonial brewers transferred the beer into wooden kegs or barrels, storing them in cool cellars. This aging period could last from weeks to months, allowing the beer to mature, mellow, and naturally carbonate. Aging not only enhanced the flavors but also improved the beer’s clarity and overall quality.

Here’s a quick breakdown of the fermentation and aging process:

| Stage | Duration | Purpose |

| Fermentation | Several days | Convert sugars into alcohol |

| Initial Aging | Weeks to months | Mellow and mature the beer |

| Final Aging | Additional weeks | Achieve desired taste and clarity |

This structured approach was essential to producing the high-quality beer that became a staple of the time.

Conclusion

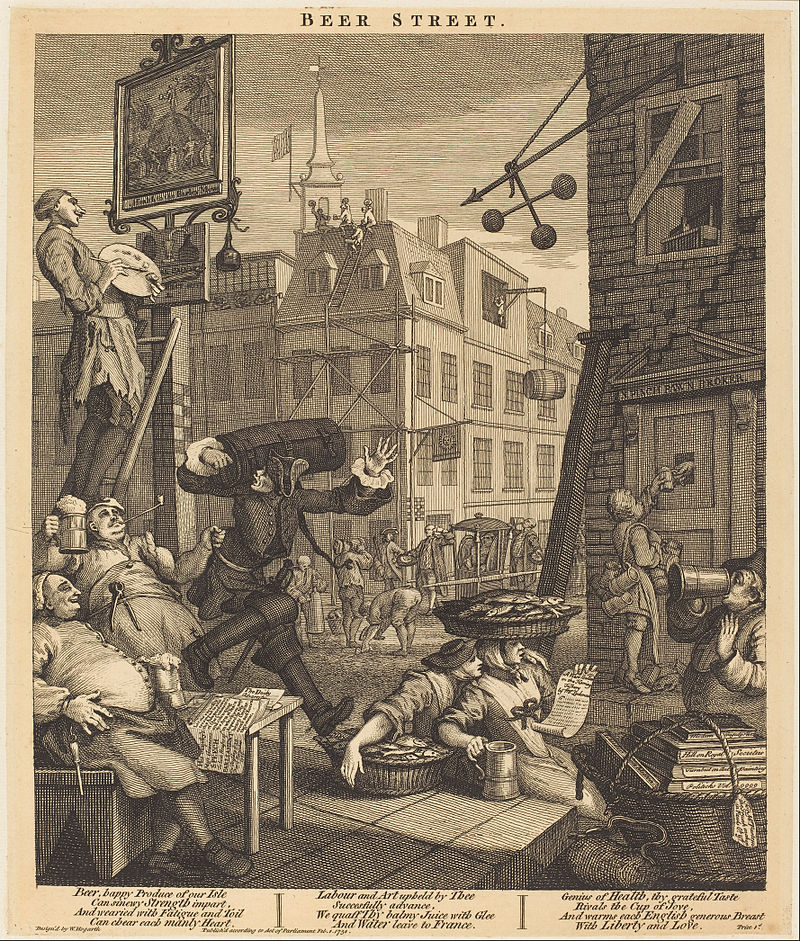

Brewing beer in the 17th century wasn’t just a series of steps; it was a dance of science and tradition, yielding a beverage that was both safer to drink than water and delightfully rich in flavor. This time-honored craft not only quenched thirst but also brought communities together, providing a staple of everyday life that was enjoyed by many. So, next time you sip a cold beer, remember the legacy of those early brewers and the centuries-old techniques that continue to shape the flavors we savor today.