Weighbridges or truck scales are special devices used to measure the weight of heavy vehicles like trucks, buses and trailers. These devices are used in go-down centres and production plants to weigh goods in transit for safety compliance and tracking. Road authorities use the bridges to perform inspections, and ensure vehicles meet road safety requirements. This is important as heavy vehicles have specific maximum load restrictions based on the axle weight. The weighing function is executed as the vehicles pass over the bridge. Most spots are set up around toll stations and special zones on the highways.

The weighbridges use pressure sensors, indicators and controllers to accurately measure and monitor the weight of the vehicles. These components work in synergy to improve accuracy, but they serve different functions. Here’s how each component is used in a weighbridge system:

Pressure Sensors (Transducers)

Pressure sensors, or load cells, are the main components in weight bridges. They are placed strategically under the weighing platform of the bridge to measure the force exerted by the vehicle’s weight. The load cells work as pressure transducers, converting weight into an electrical signal. This is typically achieved through changes in resistance or voltage. When the vehicle drives over the bridge, the load cells pick up the pressure changes and provide signals that are proportional to the weight input.

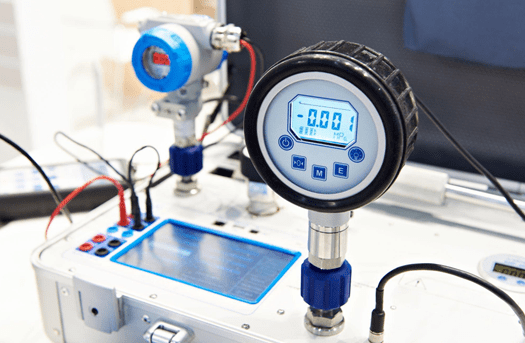

Pressure Indicators

The pressure indicator displays the weight of the vehicle. The electrical signals generated from the pressure sensors are sent to a signal conditioning unit that processes the input and converts it into a weight value. The value is then displayed on a digital screen or analogue dial for the operator to see the weight in real time.

Pressure Controllers

This is an optional component found in some advanced weighbridge systems. A pressure indicator controller is used to ensure accurate and consistent measurements. They calibrate and maintain the load cells’ performance over time. Pressure controllers are also used to provide control over the weighing process. For example, you can use the controllers to apply corrective adjustments to account for temperature variations or other environmental factors that could affect the accuracy of the weighing process.

The process of using a weight bridge is straightforward. The technology is used in various industries. These include;

Transport and logistics

Truck terminals, distribution centres and shipping yards use weighbridges to accurately take the weight of inbound and outbound trailers, trucks and shipping containers. This ensures vehicles are not overloaded and comply with legal weight limits for road safety.

Agriculture

Weighbridges are used on large agricultural facilities to weigh livestock, produce and other equipment. The information helps with shipping calculation, inventory management and compliance with regulations.

Manufacturing industry

Manufacturing plants use weight information to monitor raw material deliveries, shipments and inventory control. Weight is also used to automate packaging.

Waste management and recycling

Disposal fees are calculated based on weight. Therefore, waste management plants use weighbridges to generate invoices and monitor the waste management process.

Construction

Mining and construction sites use weighbridges to monitor raw materials, construction aggregates and minerals. This helps track transportation and consumption for project management.

Due to the varied applications, weight bridges come in different configurations. The choice of weighbridge depends on the weight, location, and space availability. Full-length weigh bridges extend the entire length of the vehicle, allowing accurate measurement.

Alternatively, Axle weighbridges measure the weight of individual axles, ensuring compliance with road safety laws. In-motion weighbridges are often used in toll booths and inspection stations to monitor weight without causing traffic congestion. Other configurations include muti-deck, rail, pitless and pit-type weighbridges.

The advantages of operating weighbridges are innumerable. However, it’s imperative to match the bridge design with your needs. Talk to experts and gain more insights on what’s available.