In today’s fast-paced manufacturing industry, businesses constantly seek innovative ways to smooth their production processes and maximize efficiency. One such solution that has changed the textile and packaging industries is the top automatic reeling machine. This advanced equipment offers numerous benefits, enhancing productivity and ultimately leading to greater profits.

Automatic reeling machines are designed to automate the winding and reeling of various materials, such as yarn, thread, wire, and even plastic films. They are equipped with cutting-edge technology and features that eliminate the need for manual labour, resulting in significant time savings and improved operational efficiency.

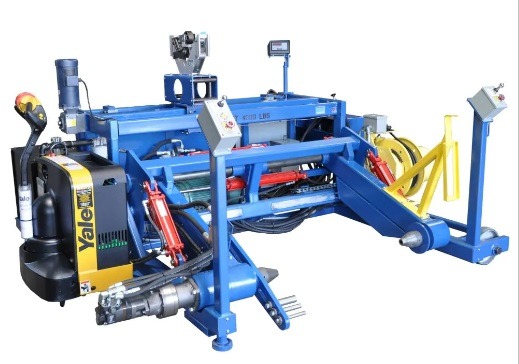

Reel Power Industrial provides top-notch reeling, spooling, and coiling solutions tailored to your requirements. With a team of six highly skilled engineers who specialize in these services, you can be sure of receiving customized solutions that meet your needs.

Top Advantages of Automatic Reeling Machine

1. Automation

Automatic reeling machines are great because they can handle a lot of stuff without needing too much help from people. These machines have special sensors and settings that ensure things get wrapped up neatly and correctly, even if the property is complicated. This means there’s less chance of people making mistakes, and we don’t have to keep watching them constantly. Instead, the people can work on other important things while the machine handles the wrapping. This is what Reel Power Industrial’s Automatic reeling machine offers.

2. Speed

Automatic reeling machines are super fast! They can wrap things up quickly compared to doing it by hand. This greatly helps businesses because they can get things done in less time. It’s fantastic for meeting deadlines and ensuring customers get their orders on time. These machines are like speed champions that boost productivity!

3. Versatility

Automatic reeling machines are like chameleons—they can handle different materials and sizes. You can tell them what you need, and they’ll adjust accordingly. This is super useful because it means that manufacturers can keep up with people’s wants without needing many different machines or making significant changes. They can be flexible and make many other products without any hassle. It’s like having a device that can do it all!

4. Reduce labour costs

In addition to efficiency gains, automatic reeling machines contribute to cost savings in the long run. By automating the reeling process, businesses can significantly reduce labour costs associated with manual winding. Furthermore, the precision and consistency achieved by these machines minimize material wastage, resulting in lower production costs and increased overall profitability.

5. Promote safety

Moreover, automatic reeling machines promote a safer working environment. Manual reeling can be physically demanding and increase the risk of injuries, such as strains and repetitive motion injuries. By automating these tasks, workers are relieved of strenuous manual labour, reducing the likelihood of accidents and improving employee well-being.

6. Consistency

Implementing automatic reeling machines also allows manufacturers to maintain high product quality standards. The advanced technology employed in these machines ensures uniform winding tension, preventing material distortion or damage.

7. Sustainability

Finally, automatic reeling machines contribute to sustainability by reducing energy consumption and material waste. These machines are designed to optimize energy efficiency, consuming only the necessary power for the reeling process. Additionally, the precise winding achieved by automatic reeling machines minimizes material waste, reducing the environmental impact of excess production and disposal.

Bottom Line

In conclusion, automatic reeling machines offer numerous benefits for streamlining production processes. Embracing this advanced technology allows businesses to stay competitive, meet customer demands effectively, and drive sustainable growth in today’s fast-paced manufacturing landscape.