For businesses seeking to invest in quality plastic chairs for their customers, gaining a better understanding of the manufacturing process is crucial. Investing in the best processes that meet your needs will then become possible. By identifying the best manufacturers for you to work with, you’ll also be able to make better choices. A well-made plastic chair is a good investment, especially if it is durable and of high quality.

You can scale your business with these chairs since they can cater to the needs of your customers. Let’s examine the different ways we manufacture quality plastic chairs in this post. Hopefully, you’ll gain a more comprehensive understanding of what’s involved.

Plastic Chair Manufacturing Process

What is the process of plastic chairs manufacturing? To understand the entire process, discuss the different processes used to manufacture plastic products. There are three methods of making plastic chairs. Each method uses a mold. Intricacy and technology distinguish these chairs, however.

Rotational Molding

The process of creating plastic chairs involves creating metal molds and carving them into desired shapes. One of the most popular furniture molding techniques is rotational molding. In this process, we inject the plastic powder into large metal molds with the application of heat. The plastic powder melts and is ready to be molded. We use mechanical forces to rotate the molds in three dimensions to evenly distribute the polymer inside. The machine stops after the polymer mixes evenly and cools down. Once the chair comes out, the mold gets hollow to the core.

Injection Molding

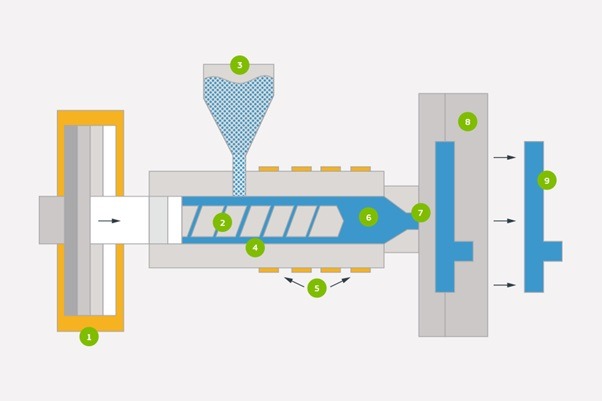

Injection molding is another method of producing plastic chairs. It also uses metal molds. Injection molding produces solid pieces rather than hollow ones.

This type of mold, which does not spin, heats polymers at a preset temperature and rate. Once it is hot enough, the polymer moves into the mold and gets cold.

As the process of pouring the plastic is slow, it may cause the mold to dry out quickly. We need precision in this type of molding. In the end, an uneven product will result from the rapid pouring of the plastic. A seamless molded plastic chair, however, is the result any time this is done correctly.

Gas-injection Molding

Another option is to blow gas at high speed into the mold to force the plastic out of it. Gas-injection molding is the technique used for this. Creating channels in the plastic would reduce the weight without compromising the strength of the chair. The chair gets its shape as the molten plastic rushes into certain areas of the mold.

Injection molding uses a similar process. In plastic chairs that are made using this technique, the parts are hollow while at the same time being solid. Gas-injection molding, however, is mainly done with gas. When the gas gets inside the mold, it rotates at a high speed.

Types Of Plastic Chair Based On Raw Material Used

Plastic chairs come in a wide variety. You can classify them according to the kind of plastic they’re made of. There are primarily two types of plastics: thermoplastics and thermosetting.

Thermoplastics

When exposed to heat, this plastic can be softened and molded, then it can be hardened after cooling. Several reheats and reshaping can be performed without affecting the chemical properties of the plastic. It is easy to recycle, upcycle, and reshape these materials for chairs. The most common thermoplastics are:

Nylon

The plastic product manufacturing industry widely uses nylon and other thermoplastics. Their strength and malleability make them highly desirable. You can also stretch them into strings. You can mold nylon into any shape you want. It is also very comfortable to sit on these chairs for long periods due to their weather resistance.

Acrylic

Acrylic is also one of the most widely used thermoplastic types. UV-resistant and easy to keep clean, acrylic chairs are very popular. However, they are rigid and less adaptable than nylon. On the other hand, acrylic chairs are ecologically beneficial.

PVC

In addition to being stiff, rigid, and lightweight, this type of plastic is also flexible. In contrast to other thermoplastics, it is less flexible. This makes it more economical and durable than other thermoplastics. Once you purchase PVC chairs, there is no maintenance necessary.

Polypropylene

Polypropylene chairs are lightweight and highly durable. It resists mildew, weather degradation, and any type of damage. It has a natural appearance and touch, making it unique.

Polythene

Polythene is a popular thermoplastic material. There is a waxy texture to this shabby plastic variant. Also, it is capable of being molded and twisted multiple times. In addition to being impact-resistant, robust, and dent-resistant, these chairs are rust-proof as well.

Thermosetting Plastics

Thermosetting plastics are the result of heating a polymer to high temperatures and then cooling it down. Polymers are liquids at first, but they solidify irreversibly on the application of heat. Once set, thermosetting plastics cannot be reshaped by heating. The plastic becomes hard and rigid. Excellent plastic chairs can also be made with thermosetting plastics. Plastic armchairs may not be recyclable, and that’s the only concern. The following types of thermosetting plastics are suitable for chairs:

Bakelite

It is a synthetic blend of plastics. Furniture made from it is sturdy and durable. It is a robust material that will last for a long time. The Bakelite type of plastic, however, is not regarded as the safest. When possible, it is best to avoid it and choose plastic furniture materials that are safer and more durable.

Epoxy Resin

Before it solidifies, this type of plastic is present as a paste. It is lightweight and strong. The structure of plastic chairs does not use epoxy resin. Chairs with plastic seats are coated with this material to protect them. It prevents any abrasion, denting, or degradation. Epoxy resin has other uses as well. There are various applications for this chemical, including metal coatings, electronics, electrical components, LEDs, insulators, and adhesives.

Melamine

Thick, thermoplastic, and strong, are the characteristics of these plastics. Molding allows you to create any shape but reshaping it is impossible. Thermosetting plastics, such as Melamine, have high durability. Melamine also finds its use in dinnerware, laminate flooring, and dry-erase boards. Melamine also reduces noise in rooms.

Conclusion

Chairs made from plastic come in all of these varieties. You must select one that you like carefully. When used long-term, thermoplastics are the best option. It is also practical to use thermoplastic polypropylene as a material. Polypropylene is more environmentally friendly than other plastics. We hope this guide will impart valuable information and makes your job easier while manufacturing plastic chairs.