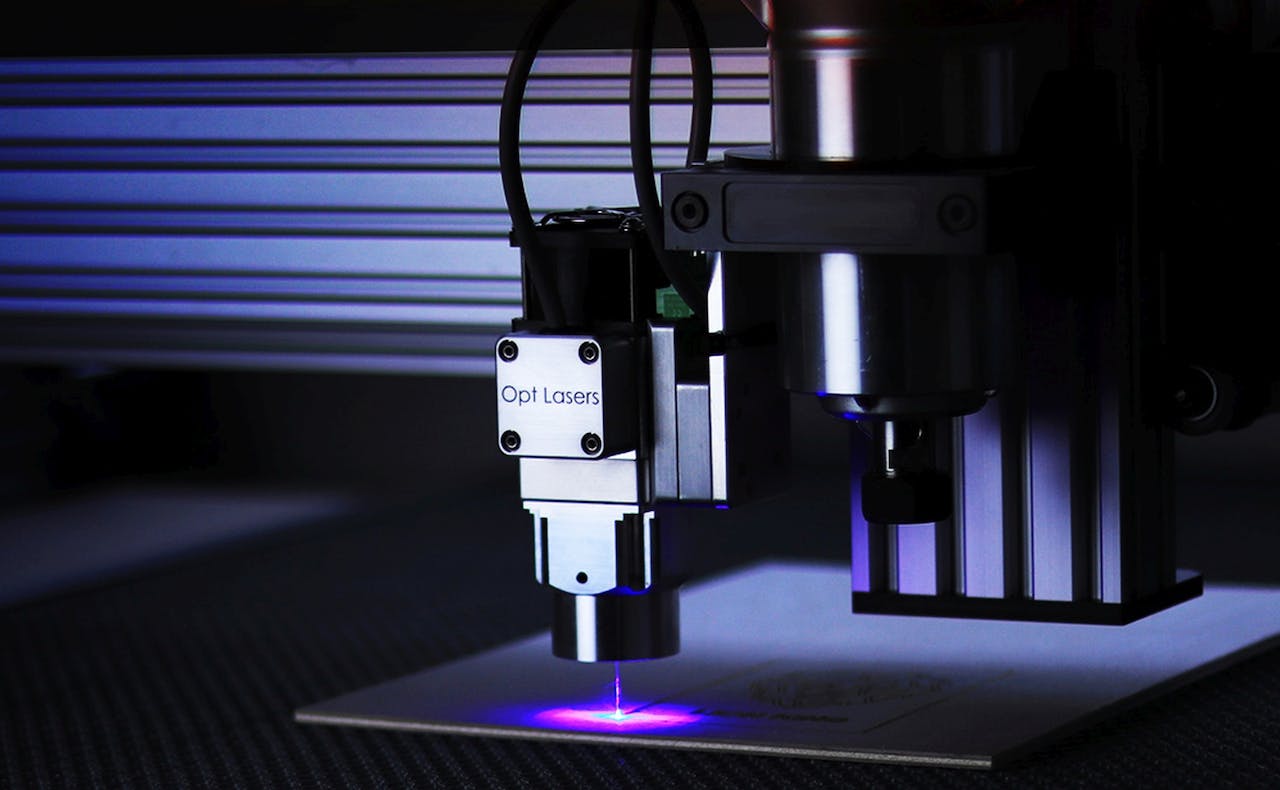

If you are looking for a new, more effective cutting process, consider putting laser cutting at the top of the list. Today, precision laser cutters are being used in countless industries and there are several reasons for this.

Keep reading to learn how laser cutting became so popular and the reasons you should consider using it in your business activities.

The Growing Need for Precision Laser Cutters

Production and manufacturing processes around the world have been innovating and developing at a growing rate. As innovation evolves, all the processes and the people driving this innovation evolves, as well.

Even though more conventional types of cutting worked well, a need arose for a safer, more reliable, and more efficient cutting process. The solution was the development of laser cutting.

The use of a Laser Cutter allows you to work faster with a higher level of precision than any other method available today. Due to all the advantages, this is now considered the primary cutting method for an array of industries, including the medical field, semiconductors, electronics, aerospace, and automotive.

Benefits Offered by Laser Cutting

Now that you understand how laser cutting became a primary method for an array of industries, it’s time to learn more about the specific benefits it offers.

It’s a Non-Contact Process

What this means is that the beam used to cut doesn’t ever physically touch the material being cut. Instead, items are cut through the heat produced by the laser.

What this means is that the damage to the material is minimized and the need for expensive repairs for moving parts that come in contact with the work surface is avoided.

Reduced Power Consumption

This is a crucial advantage in today’s world where people are looking for methods to work smarter, not harder while increasing productivity and reducing costs. Acoording to DXTECH Laser, A laser cutting machine is only going to use approximately 10kW of power, where other cutting processes use approximately 50kW of power.

A Safer Method of Cutting

As the need for increased production grows, there is also a need for increased safety. Using a laser cutter is much safer than other cutting methods. That’s because the beam is sealed in a lightbox.

Ability to Cut Many Materials

Regardless of if you are working with glass, wood, plastics, diamonds, metal, or another material, a laser cutter will have no problem cutting it. Even better, lasers have the ability to cut much more intricate and complex shapes than other methods of cutting used today.

Should You Use a Precision Laser Cutter?

As you can see, there are more than a few benefits offered by using a precision laser cutter. If your business is searching for a faster and more efficient way to cut various materials, consider this option.

If you are looking for more information and resources about an array of topics, check out some of our other blogs.