When it comes to reheating food, microwaves have become an indispensable kitchen appliance in today’s fast-paced society, sparing us both time and effort. Typically, microwave food covers are constructed from plastic and are available at kitchen appliance retailers for as little as two dollars. They are essential for safeguarding food and preventing spillage during microwave heating, thereby eliminating the need for hours of subsequent cleansing. Covering food lightly while reheating it in the microwave maintains vapor in close proximity to the food, which aids in moisture retention and ensures an even reheating of the dish.

This article will examine the various plastics that are utilized to construct microwave covers.

Basics of Plastics in Kitchenware

In the contemporary era, plastic culinary containers have emerged as an indispensable commodity. Although the use of plastic has been the subject of some controversy, it is essential to recognize that plastic kitchen containers can provide a number of advantages in terms of promoting a healthy lifestyle.

From the containers in which we store the food to the kitchenware and appliances we employ to prepare it, the food is frequently encircled by plastic in our kitchens. Completely avoiding plastic in the kitchen is virtually unattainable. However, a small amount of knowledge can significantly reduce potential dangers.

Plastic containers for use in the household are renowned for their resilience and longevity. In contrast to glass containers, fallen plastic containers are less susceptible to breakage or shattering. For individuals who are constantly on the move or families with young children, this characteristic renders them a viable option.

When used properly, plastic kitchen containers can be safe and hygienic, contrary to popular belief. Obtain containers bearing the BPA-free label, which specifies the absence of detrimental substances such as bisphenol-A. Plastic containers that are free of BPA offer a secure alternative for food storage while also reducing potential health hazards.

Types of Plastics Used in Microwave Covers

Polyethylene (PE)

Polyethylene, depending on the variety, is a thermoplastic polymer with a variable crystalline structure and an extensive array of applications. It is among the most abundantly manufactured plastics on a global scale, with tens of millions of tons produced annually. In addition to translucent food wrap and shopping bags, detergent bottles and automobile fuel tanks are manufactured from polyethylene. Additionally, it can be spun or divided into synthetic fibers or altered to acquire the elastic properties of rubber.

Polyethylene (PE) plastic is resilient, tear-resistant, and flexible. When these three qualities are required for poly bags intended for packaging heavy-duty items, they are all essential. As a result, industrial enterprises frequently employ polyethylene storage sacks to contain weighty, sizable components of industrial machining.

Polyethylene is composed of hydrocarbon chains, with the ethylene molecule, which comprises two carbon and four hydrogen elements, serving as its most fundamental constituent. Polyethylene is produced when ethylene molecules are combined in linear or branched chains. By breaking the double bond between the two carbon atoms, a free radical is produced that proceeds to bind with the subsequent ethylene molecule. The macromolecules are bound together in a crystalline structure by intermolecular forces rather than covalent bonds. An increase in density corresponds to a decrease in the number of side branches, which in turn results in a reduction in crystallinity, as evidenced by the variations in properties among distinct varieties of polyethylene.

Although polyethylene is resistant to the elements, prolonged exposure to sunlight may cause it to brittle. The aforementioned constraint may be surmounted by incorporating UV stabilizers. It is combustible and will continue to burn with a yellow-tipped blue flame after the ignition source is withdrawn; this will result in the plastic dripping. Polyethylene cannot be imprinted or adhered to without prior pretreatment due to its surface characteristics. Whether polyethylene is opaque, milky-opaque, or transparent depends on the material grade, product thickness, and additive content.

Polypropylene (PP)

Polypropylene (PP) is a “addition polymer” composed of propylene monomers combined to form a thermoplastic material. Packaging for consumer goods, plastic components for various industries (including the automotive sector), specialized devices (such as living hinges), and textiles are among the many applications for which it is utilized.

In 1951, two Phillips petroleum scientists named Paul Hogan and Robert Banks were the first to polymerize polypropylene. Subsequently, Italian and German scientists Natta and Rehn followed suit. It rose to prominence extraordinarily rapidly, with commercial production commencing less than three years after Professor Giulio Natta, an Italian chemist, initially polymerized it.

In 1954, Natta successfully synthesized and perfected the initial polypropylene resin in Spain. The remarkable crystallinity of polypropylene generated considerable enthusiasm. Its popularity skyrocketed by 1957, at which point extensive commercial production commenced throughout Europe. Presently, it is among the most widely manufactured plastics on a global scale.

Polypropylene finds applicability in both industrial and household settings. Its exceptional qualities and adaptability to a variety of fabrication processes distinguish it as an indispensable material with a vast array of applications.

An additional advantageous quality of polypropylene is its capability to operate as both a plastic material and a fiber (such as the promotional duffel bags distributed at races, events, and the like).

Due to its versatile manufacturing processes and wide-ranging applications, polypropylene rapidly emerged as a formidable contender against several traditional alternative materials, particularly in the packaging, fiber, and injection molding sectors. It has maintained consistent development throughout the years and continues to be a significant player in the global plastics industry.

Polycarbonate (PC) and BPA

Polycarbonate (PC) plastics are a transparent thermoplastic that is inherently transparent. While the basic material is commercially produced in a range of colors (some of which may or may not be translucent), its capacity for internal light transmission is comparable to that of glass.

Eyeglasses, medical devices, protective apparel, auto parts, DVDs, lighting fixtures, and Blu-rays are all constructed from polycarbonate. Polycarbonate, being an inherently transparent amorphous thermoplastic, possesses advantageous properties such as superior internal light transmission capability compared to glass and greater impact resistance than numerous frequently employed alternative plastics.

The formation of the primary polycarbonate material occurs through the chemical reaction between phosgene COCl and bisphenol A (BPA). The initial phase of the synthesis entails subjecting bisphenol A to sodium hydroxide treatment, which deprotonates its hydroxyl groups.

A chloroformate is produced when diphenoxide reacts with phosgene; this compound is subsequently attacked by another phenoxide. Annually, approximately one billion kilograms of polycarbonate are generated in this manner.

In addition, the malleability of polycarbonate enables its formation at ambient temperature without undergoing splitting or breaking, and it can be reshaped into an amorphous state even in the absence of thermal application. The term “thermoplastic” concludes with a description of the characteristic of polycarbonate and comparable plastics to transform into liquid form at their melting point. This property facilitates recycling and injection molding, among other applications. For more information on injection molding, you can read our article, About Plastic Injection Molding.

Safety and Health Concerns

Plastic items encountered on a daily basis comprise a multitude of compounds, a subset of which have been scientifically linked to adverse health effects. Pthalates and bisphenols, in particular, are recognized for their ability to disrupt the endocrine system and cause reproductive dysfunction, fertility concerns, behavioral disturbances, and asthma in children. Particularly worrisome is the exposure to these substances throughout fetal development, infancy, and childhood.

Further investigation is required to comprehensively comprehend the health ramifications of these additives; however, it is evident that at least a subset of them are cytotoxic, and they can all permeate from the plastic products that we routinely handle.

There is evidence linking phthalate exposure—a compound that imparts flexibility to plastic—to diminished sperm quality in males and shortened distances between the anus and scrotum in male infants.

According to the Pediatric Environmental Health Specialist Unit, fetal BPA exposure has been linked to premature birth, alterations in breast and prostate cells, early onset of puberty, obesity, diabetes, and cardiovascular disease.

In order to mitigate avoidable hazards, professionals recommend that individuals cook food in glass or ceramic containers and replace plastic cookware bearing the label “microwave-safe” that has undergone color changes or scratches.

Regulatory Standards and Labels

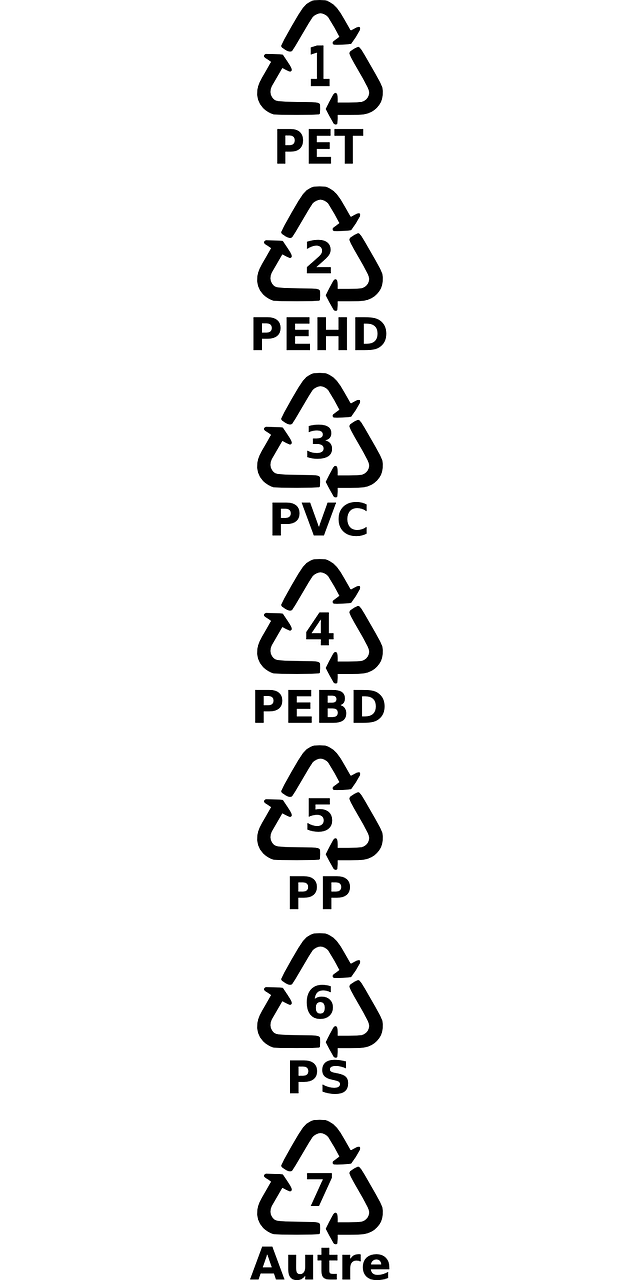

If it is unavoidable to microwave food in plastic containers, then inspect the recycling codes printed at the bottom of the container. Those codes indicate the type of plastic utilized; avoid products bearing codes 3 or 7. It is recommended against reusing margarine tubs, take-out containers, whipped topping dishes, and other one-time use containers by the USDA Food Safety and Inspection Service. Such containers have an increased likelihood of melting, thereby facilitating the leaching of chemicals into food.

Manufacturers are also permitted by FDA regulation to establish the “conditions of use” for any product, such as whether it is “microwave-safe,” “dishwasher-safe,” or reusable. “The manufacturer is responsible for ensuring that their product is appropriately labeled to indicate its safety when used as intended.

Even for containers bearing the “safe” labels for the microwave and dishwasher, plastic and heat do not blend well, according to experts. Due to the fact that elevated temperatures facilitate the disruption of chemical bonding within plastic, there is a potential for an accelerated rate of chemical migration from the container into the food upon exposure. Even in sun-exposed water bottles, greater rates of chemical migration have been observed by scientists.

Deference to manufacturers by the FDA regarding “conditions of use” may also affect takeout containers from delis and restaurants, which many individuals reuse and clean in the dishwasher, if they are not constructed to withstand such wear and strain. In the absence of additional testing and greater manufacturer and FDA transparency, experts are unable to determine whether these containers discharge chemicals at a faster rate than reusable containers.

Before utilizing an unlabeled microwave utensil, it is possible to ensure that it is microwave safe through testing. That is how to accomplish it. To test, pour one cup of tap water into a measuring vessel made of glass. While placing the water in the microwave, avoid coming into contact with the utensil that is undergoing testing. Microwave for one minute on high. Warm or heated utensils are not safe for use in the microwave due to the presence of metal in the material or glaze. Avoid using it. When heated in the microwave, the utensil and/or the underside of the oven may fracture.

Safe Use of Plastic Microwave Covers

Undoubtedly, food preparation in the microwave is enhanced by the utilization of covers, which serve to prevent contamination, retain moisture, and ensure uniform cooking. According to the Food and Drug Administration, microwave-safe plastic wrap should be used sparingly to allow vapor to escape and should not come into direct contact with the food. Certain plastic covers bear labels that specify a minimum distance of one inch between the plastic and the food when subjecting it to microwave heating.

Aluminum foil, plastic storage bags, and grocery bags should never be used in the microwave. Plastic containers suitable for the microwave that have been scratched or rendered rough should be discarded.

Always read the instructions before placing covers in the microwave. In general, white microwave-safe paper towels, wax paper, parchment paper, plastic covers, and cooking bags are safe for use in the microwave.

Plasmid-safe plastic wrap should not come into direct contact with the food. Certain plastic wrap labels specify that a minimum distance of one inch should exist between the plastic and the food when using the microwave.

Use commercial ceramic, glass, or microwave-safe plastic coverings when placing food in the microwave. Microwave-safe plastic wraps should also be utilized. Ensure that steam can escape by loosening the lid or wrapping; otherwise, opening the container could cause it to warp, melt, or unleash a very hot rush of vapor or food.

Alternatives to Plastic Microwave Covers

Despite the fact that plastics have become an indispensable component of our everyday existence, it is vital to consider their effects on our health. Numerous studies have recently demonstrated that plastic pollution endangers both human health and environmental health.

We are able to make better judgments for ourselves and our families when we are better informed. Minimizing our dependence on plastics concurrently diminishes our exposure to micro plastics and the corrosive compounds employed in their production.

Glass is an alternative to plastic when it comes to microwaving. In contrast to plastic, which is frequently produced using fossil fuels, glass is composed of silica. This renewable resource is chemical-free, meaning it will not infiltrate into your food or body. And it is simple to recycle, whether you reuse glass jars to store leftovers or simply toss bottles in your recycling receptacle to be repurposed. Although glass may shatter when dropped, it remains unaffected by microwave melting.

Straw and wooden (metal-free) containers, oven cooking bags, wax paper, parchment paper, and vented plastic bags are all microwave-safe. Utilizing paper products that have received explicit approval for microwave cookery ensures their safety.

The oven-safe symbol is the simplest and most effective method to determine whether a piece of cookware is safe for use in the oven. In general, food-grade silicone, copper, ceramic, cast iron, and stainless steel are utilized to construct oven-safe cookware.

Certain pans feature a non-stick coating, which may reduce their resistance to heat. Additionally, their lids might not be oven-safe. For information on both of these factors, consult the pan’s instructions or contact the manufacturer.

While ceramics are generally acceptable, those adorned with adhesive designs or glazed should be inspected for an oven-safe label. Although it is safe to use oven-safe glass, avoid subjecting it to temperature extremes. Avoid, for instance, directly placing it in a heated oven or transferring it from a hot oven to cold water.

Environmental Impact

Although plastic packaging enhances convenience, it comes at what cost? Its longevity guarantees that it will never vanish. Contained within our food packaging and other aspects of our daily lives, it has contributed to pervasive pollution. What then becomes of plastics once they have been discarded? While a portion is recycled and another portion is incinerated, the vast majority is disposed of in landfills or enters the environment as waste.

Plastic waste is a significant environmental issue that requires everyone’s participation in order to be reduced. Proper plastic recycling constitutes a critical stride in the right direction. However, many individuals who are not separating specialists continue to harbor skepticism regarding the recycling of plastic items comprised of various materials.

Plastics vary in composition; therefore, understanding which varieties are recyclable is crucial. The recycling symbol is typically located at the base of the product. Observe and determine the number that appears within the symbol. The aforementioned number denotes the plastic variety, with certain varieties being non-recyclable.

The official recycling rate of plastic packaging is reported to be approximately 10% on average, with variations observed across different countries. Plastic recycling in the United States has decreased in recent years, from 9% in 2018 to 6% in 2021, reportedly as a result of the cessation of plastic exports to China. Although mixed plastic packages were recycled in China, they ultimately wound up in landfills.

To recycle plastic in an appropriate manner, it is critical to be aware of the materials accepted by your local recycling program. Additionally, inquire with nearby retailers regarding the availability of in-store receptacles designated for difficult-to-recycle plastics. By adopting these minor measures, each of us can contribute to waste reduction and environmental protection. Prior to recycling, contemplate decreasing your plastic usage. To avoid using single-use plastic, bring your own reusable containers, water bottles, and backpacks. Reusing plastic items rather than discarding them is an excellent method to reduce waste.

Conclusion

Although microwave-safe plastics do exist, there are certain precautions that must be taken into account prior to purchasing them. Particularly intimidating are properties and terms such as BPA-free and microwave safe, which appear to be extremely scientific in nature and potentially hazardous if not adhered to. Improperly microwavable plastics can result in a variety of complications, including BPA leaks, chemical shredding that renders the plastic unrecyclable, and life-threatening illnesses.

A critical aspect of plastics is that they are composed of compounds that have the potential to cause acute and chronic harm to individuals. Keep in mind that there are various types of plastics, and making the incorrect selection can have severe consequences for both the individual’s life and their microwave. Regarding microwave-safe containers and plastic, it is therefore essential to verify and adhere to a number of the recommended guidelines.

References:

- That Plastic Container You Microwave In Could Be Super-Toxic. Olivia B. Waxman https://time.com/4229503/plastic-in-microwave-is-it-safe/ MAY 4, 2016

- https://www.fsis.usda.gov/food-safety/safe-food-handling-and-preparation/food-safety-basics/cooking-microwave-ovens

- Are plastic containers safe for our food?. Lauren Zanolli https://www.theguardian.com/us-news/2020/feb/18/are-plastic-containers-safe-to-use-food-experts. February 2020

- https://sensoneo.com/waste-library/how-to-properly-recycle-plastic/